This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

New process makes battery production more eco-friendly

Switching from gas-powered cars to electric vehicles is one way to reduce carbon emissions, but building the lithium-ion batteries that power those EVs can be an energy-intensive and polluting process itself. Now researchers at Dalhousie University have developed a manufacturing process that is cheaper and greener.

"Making lithium-ion cathode material takes a lot of energy and water, and produces waste. It has the biggest impact on the environment, especially the CO2 footprint of the battery," says Dr. Mark Obrovac, a professor in Dalhousie University's Departments of Chemistry and Physics & Atmospheric Science.

"We wanted to see if there were more environmentally friendly and sustainable—and less expensive—ways to make these materials."

Most electric vehicle batteries use lithium nickel manganese cobalt oxide (NMC), with the elements mixed in the crystal structure of the cathode. They are typically made by dissolving the elements in water then using the crystals that form when the elements come together as a solid.

That process takes a lot of water—which then has to be treated to clean it—and energy, which is the main source of the cost and carbon footprint of the batteries. Using the Canadian Light Source (CLS) at the University of Saskatchewan, Obrovac and his team investigated whether they could use an all-dry process to get the same results while saving energy, water, and money.

Their work has been published in two papers, in ACS Omega and the Journal of the Electrochemical Society.

"We wanted to see, can you get the same quality if you take dry materials and combine them using simple processes that you'd find in any large-scale factory and heat them up," he says. "And under what conditions can you do that to get commercial-grade material while cutting out the water and the waste?"

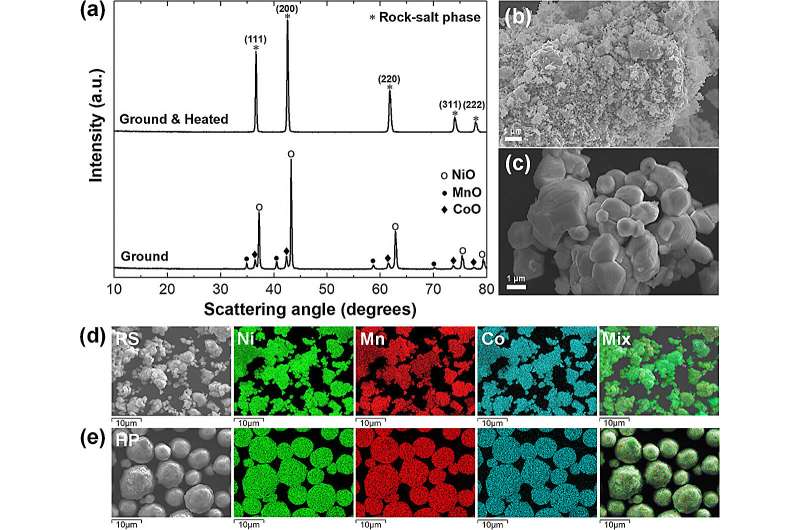

Cathodes made from dry materials are sometimes not as homogeneous as those made in water, so the team tried a variety of methods using different oxides and heating regimes under different temperatures and pressures to determine what worked best.

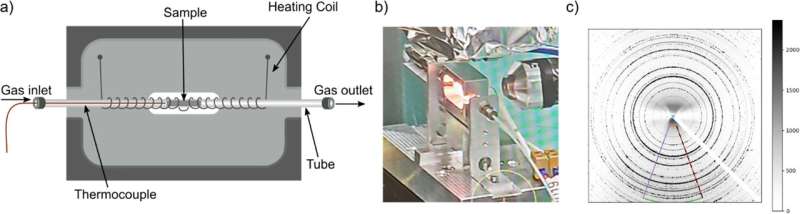

They used the Brockhouse beamline at CLS to peer inside the furnace as they tried these different experiments, to see exactly what was happening during the process. "What we found was important information about how we can improve the process so that what comes out is a higher-grade NMC-type cathode material," says Obrovac.

The highest quality cathodes available now are made from single crystals with particles about 5 microns in diameter. By carefully adjusting their starting materials and furnace conditions, Obrovac's team was able to reproduce those qualities using an all-dry process, making cathode materials comparable to the best ones on the market today.

Obrovac has partnered with the Nova Scotia-based battery company NOVONIX, which is using all-dry processes to produce cathode materials at the company's pilot-scale facility in Dartmouth. That facility is capable of producing 10 tonnes per annum of cathode material, with methods that offer an estimated 30% lower capital costs than the conventional (wet) methods, 50% lower operating costs, and uses 25% less energy, while requiring no process water, and generating zero waste.

"These are big numbers, it's very much a step-change in the production of these battery materials," says Obrovac. "It should result in lower-cost batteries overall with a substantially lower global warming footprint."

More information: Mohammad H. Tahmasebi et al, New Insights into the All-Dry Synthesis of NMC622 Cathodes Using a Single-Phase Rock Salt Oxide Precursor, ACS Omega (2023). DOI: 10.1021/acsomega.3c08702

Ido Ben-Barak et al, All-Dry Synthesis of NMC from [Ni,Mn,Co]3O4 Spinel Precursors, Journal of The Electrochemical Society (2024). DOI: 10.1149/1945-7111/ad3aa9