Team's flexible micro-LEDs may reshape future of wearable technology

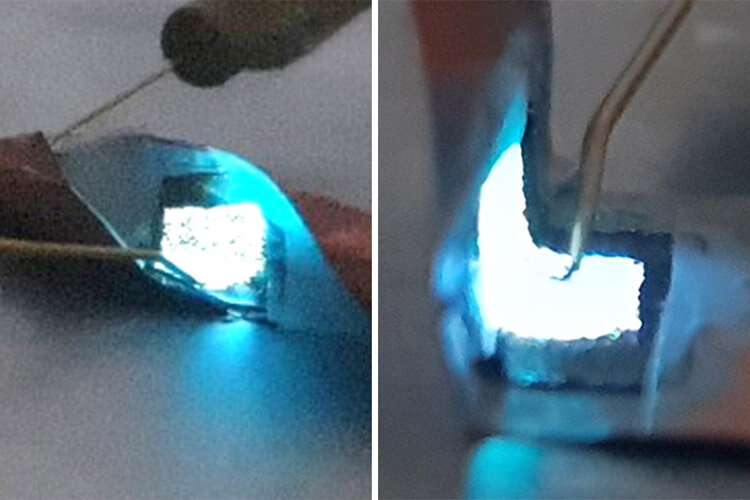

University of Texas at Dallas researchers and their international colleagues have developed a method to create micro LEDs that can be folded, twisted, cut and stuck to different surfaces.

The research, published online in June in the journal Science Advances, helps pave the way for the next generation of flexible, wearable technology.

Used in products ranging from brake lights to billboards, LEDs are ideal components for backlighting and displays in electronic devices because they are lightweight, thin, energy efficient and visible in different types of lighting. Micro LEDs, which can be as small as 2 micrometers and bundled to be any size, provide higher resolution than other LEDs. Their size makes them a good fit for small devices such as smart watches, but they can be bundled to work in flat-screen TVs and other larger displays. LEDs of all sizes, however, are brittle and typically can only be used on flat surfaces.

The researchers' new micro LEDs aim to fill a demand for bendable, wearable electronics.

"The biggest benefit of this research is that we have created a detachable LED that can be attached to almost anything," said Dr. Moon Kim, Louis Beecherl Jr. Distinguished Professor of materials science and engineering at UT Dallas and a corresponding author of the study. "You can transfer it onto your clothing or even rubber—that was the main idea. It can survive even if you wrinkle it. If you cut it, you can use half of the LED."

Researchers in the Erik Jonsson School of Engineering and Computer Science and the School of Natural Sciences and Mathematics helped develop the flexible LED through a technique called remote epitaxy, which involves growing a thin layer of LED crystals on the surface of a sapphire crystal wafer, or substrate.

Typically, the LED would remain on the wafer. To make it detachable, researchers added a nonstick layer to the substrate, which acts similarly to the way parchment paper protects a baking sheet and allows for the easy removal of cookies, for instance. The added layer, made of a one-atom-thick sheet of carbon called graphene, prevents the new layer of LED crystals from sticking to the wafer.

More information: Junseok Jeong et al. Remote heteroepitaxy of GaN microrod heterostructures for deformable light-emitting diodes and wafer recycle, Science Advances (2020). DOI: 10.1126/sciadv.aaz5180