March 29, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Inverse design method used to improve porous surface texture of 3D printed objects

A multi-institutional team of mechanical engineers and materials scientists has developed an inverse design method to improve the texture of porous surfaces on 3D printed structures. In their paper published in the journal Science, the group describes developing micrometer-sized triangles and ribbons to create a lattice upon which to build surface structures.

In the natural world, the arrangement of cells allows for the creation of unique porous surface structures—leaves, flowers and human skin all have a remarkable degree of surface variability with unique visible features and specific characteristics, such as repelling water. Recreating such features using technology as simple as a 3D printer has been impossible.

In this new effort, the research team has come a step closer to mimicking nature by developing a new way to represent such structures in a reproducible way.

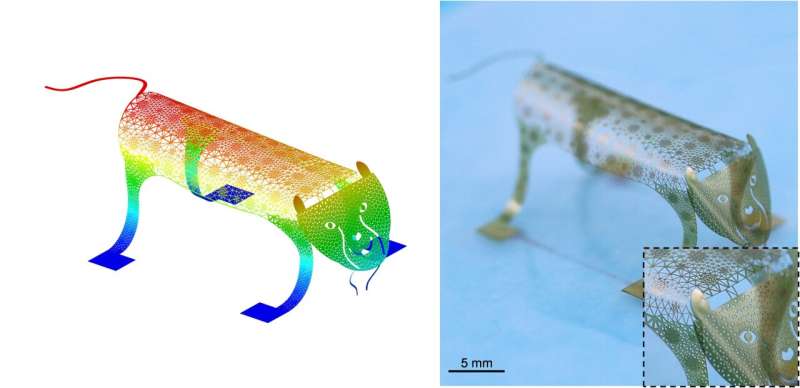

The researchers sought to replicate the way cells are arranged by creating digital lattices composed of tiny triangles and ribbons. They came to these shapes using an inverse design method (curved beam deformation theory). They then developed an application to generate desired shapes using their digital lattices.

-

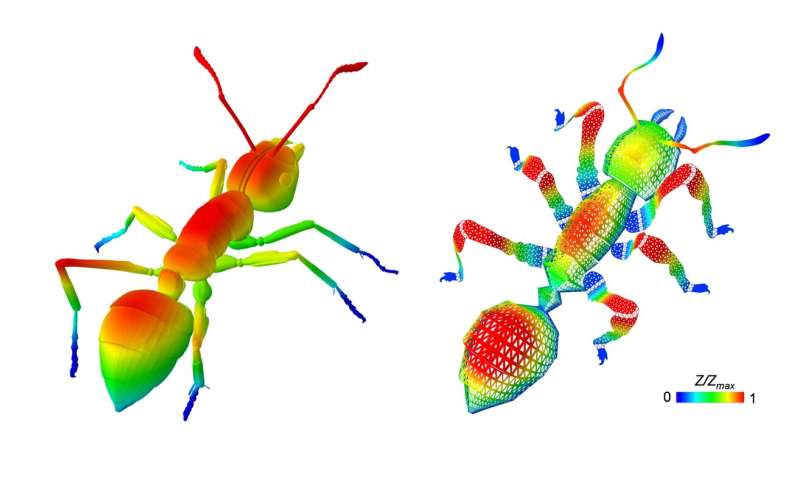

A 3D mesosurface inspired by the ant. The entire ant-like microlattice structure consisting of 4034 microtriangles and 7826 microribbons accurately reproduces the design target. Credit: Prof. Yihui Zhang (Tsinghua University) -

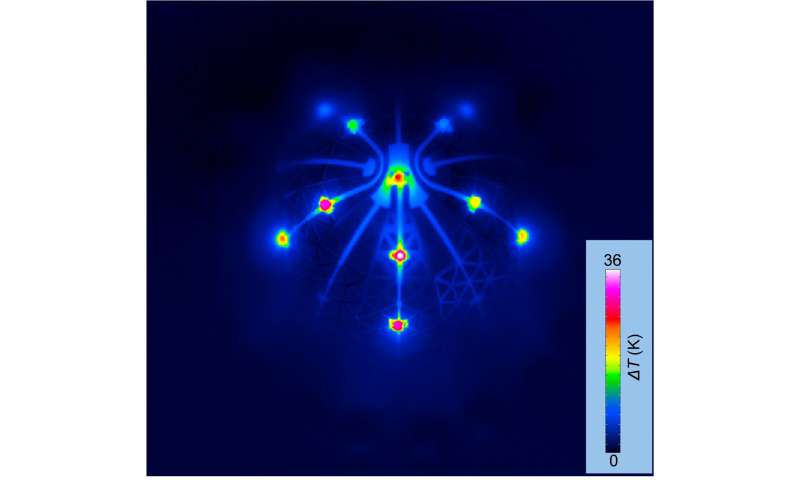

Infrared image of the breathable 3D cardiac electronic device after green LED array lighting for ten minutes. Credit: Prof. Yihui Zhang (Tsinghua University)

The application was then taught how to create such shapes using a machine-learning algorithm. The finished product was then sent to a 2D printer, which printed out a pattern onto a base that could be folded into 3D shapes. The system allowed for creating a wide variety of structures with highly porous surfaces.

The team demonstrated their system by first creating simple textured objects such as spheres. They then progressed to creating more complicated objects, such as a bell pepper, an ant and an octopus. They also note that the objects that are created can be made using a variety of materials, such as single crystal silicon, metals, chitosan and laser-honed graphene.

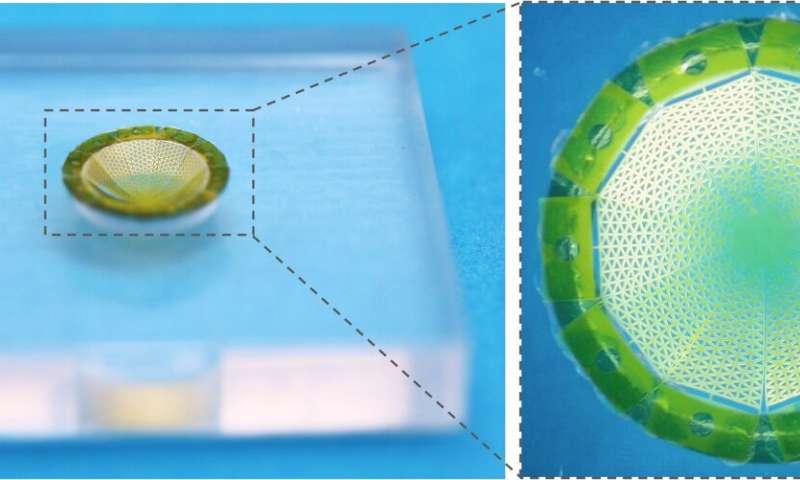

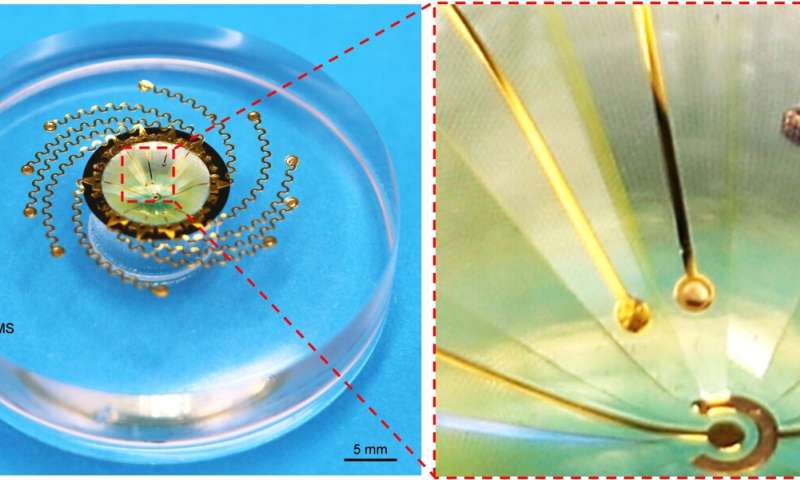

The group finished by creating a scaffold shaped like a contact lens that was embedded with sensors. Once printed, they used the structure to study the electrical properties of neurons in the back of the eye.

-

A spherical cap-shaped mesosurface based on the microlattice design was isolated from the substrate and placed upside down on the PDMS base for cell culture. Credit: Prof. Yihui Zhang (Tsinghua University) -

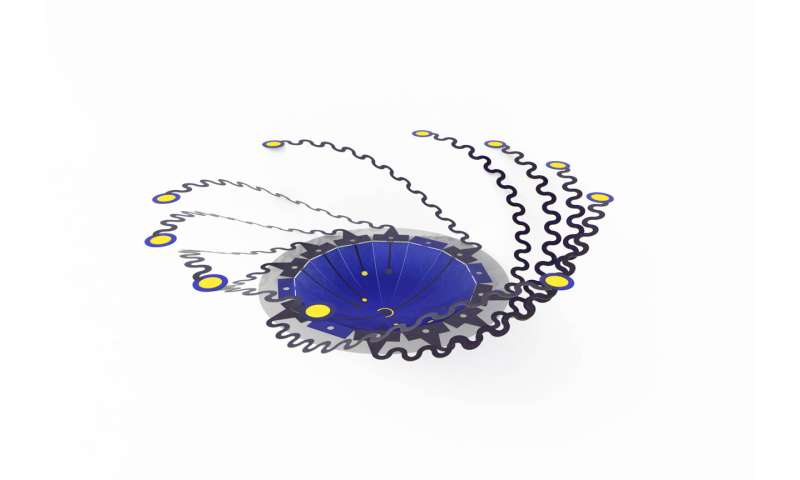

FEA result of a 3D electronic cell scaffold: A 3D assembled electronic cell scaffold based on the microlattice design. Credit: Prof. Yihui Zhang (Tsinghua University) -

Optical images of a 3D electronic cell scaffold: Isolated 3D electronic cell scaffold consisting five pairs of electrodes was placed upside down on the PDMS base for RPE cell culture. Credit: Prof. Yihui Zhang (Tsinghua University)

More information: Xu Cheng et al, Programming 3D curved mesosurfaces using microlattice designs, Science (2023). DOI: 10.1126/science.adf3824

© 2023 Science X Network