This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Introducing a novel solution for carbon dioxide capture utilization and storage

The issue of achieving the target of net-zero CO2 emissions has emerged as a matter of future survival of mankind, with the impact of climate change causing a palpable sense of crisis in the everyday lives of people. The technology of Carbon dioxide Capture Utilization and Storage (CCUS), one of the methods for achieving net-zero CO2 emissions, has drawn attention as an innovative technology for reducing CO2 emissions.

CCUS is the very technology for which Elon Musk, the CEO of Tesla Inc., announced his funding of $100 million in prize money over four years starting in 2021. However, the high energy consumption required in the process of purification, pressurization, separation, and reuse of CO2 poses a challenge to the industrial application of these technologies in practice.

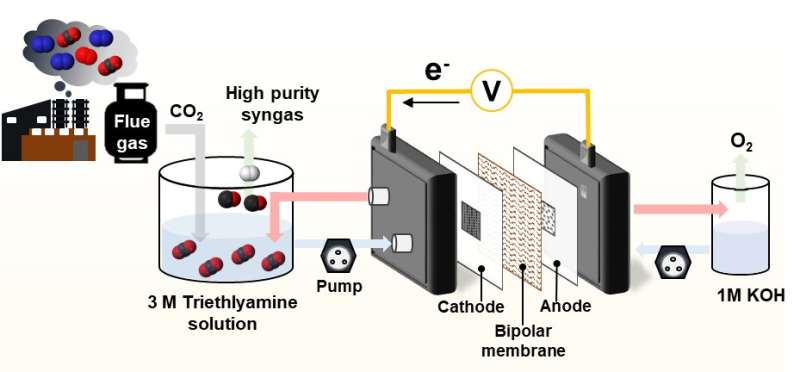

The research team led by Drs. Ung Lee and Da Hye Won at the Clean Energy Research Center, Korea Institute of Science and Technology (KIST), announced that they succeeded in developing a process for producing high-value-added synthesis gas (syngas) by direct electrochemical conversion of CO2 captured using a liquid absorbent. The research achievement is expected to provide a cost-effective solution for CCUS technology, which has restricted wider applications of the technology. The research is published in the journal Nature Communications.

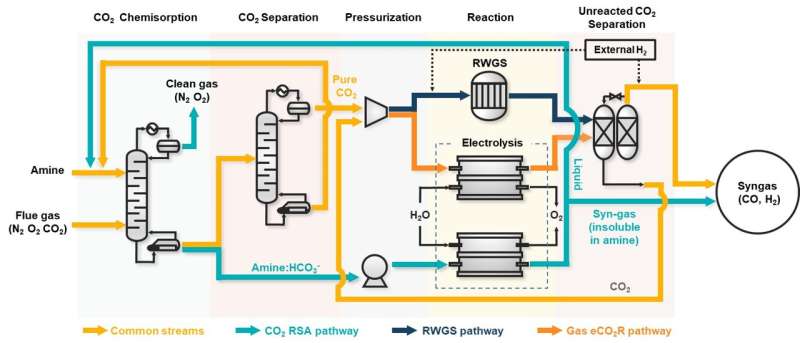

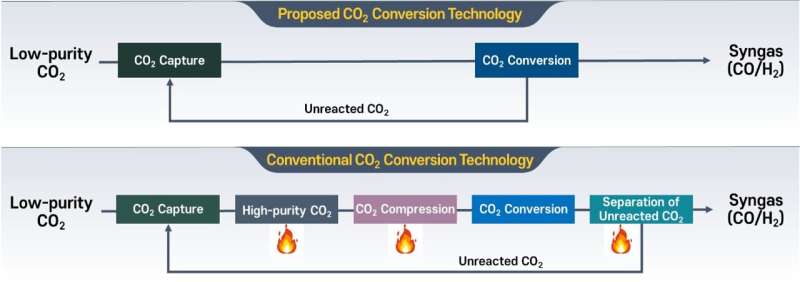

The CO2 conversion process developed by the research team utilizes the CO2 captured in a liquid absorbent; in this way, the conventional CCU pathways with complex and energy-consuming processes of purification and pressurization of CO2 for pure gaseous CO2 production are no longer needed.

For this reason, the proposed method outperforms the conventional CCUS technology, with superior cost-effectiveness and enhanced effect of reducing CO2 emissions. In addition, since unreacted CO2 is still captured in the liquid absorbent, there is no need for an additional separation process with syngas, a product from the pathway; another advantage is that the ratio of hydrogen to CO in the syngas can be more easily controlled.

Also, the research team was able to maximize the efficiency of the direct CO2 conversion in the liquid phase by conducting experiments for selecting the best absorbent, optimizing the catalyst, designing electrochemical reactor as well as testing long-term stability. In addition, simulation studies with numerical modeling of the industrial-scale process were also carried out to examine the feasibility of commercialization of the developed process. Furthermore, through techno-economic analysis and life cycle assessment, it is estimated that the newly developed CO2 conversion process will be able to reduce production costs by 27.0% and CO2 emissions by 75.7% compared to the conventional CCUS technology.

In addition, the proposed technology demonstrated an equivalent level of competitive price when compared to the current market price of chemicals dominated by fossil fuel-based technologies. In particular, in the case of syngas, the production cost was reduced by 27.02% compared to the conventional process (reduction of the production cost from $0.89/kg to $0.65/kg, and CO2 emissions from 1.13kg CO2/kg to 0.27kg CO2/kg.

If the developed CO2 conversion process is applied to a major CO2 emission source such as a thermal power plant, the proposed technology is expected to be able to produce high-value chemicals such as ethylene at a low cost while reducing CO2. Dr. Da Hye Won, a senior research scientist at KIST, reported, "The significance of the proposed technology lies in that we have achieved technological progress in the efficient production of high-concentration syngas through the electrochemical process by utilizing captured CO2."

Dr. Ung Lee, the principal research scientist at KIST, commented, "We expect that the proposed technology will be applicable to a range of electrochemical conversion systems that utilize CO2, and we plan to move onto the next stage of continuous process demonstration and verification as well as technology transfer to business entities in the future."

More information: Kezia Megagita Gerby Langie et al, Toward economical application of carbon capture and utilization technology with near-zero carbon emission, Nature Communications (2022). DOI: 10.1038/s41467-022-35239-9