This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

New method verifies carbon capture in concrete

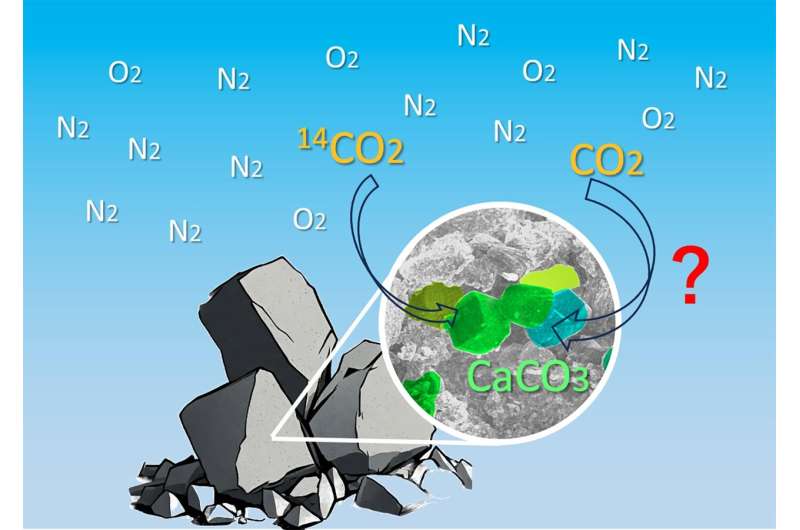

Carbon capture is essential to reduce the impact of human carbon dioxide emissions on our climate. Researchers at the University of Tokyo and Nagoya University in Japan have developed a method to confirm whether carbon in concrete originates from the raw materials, or from carbon in the air which has been trapped when it reacts with the concrete to form the mineral calcium carbonate. The work has been published in the Journal of Advanced Concrete Technology.

By measuring the ratio of certain carbon isotopes in concrete that had been exposed to the air and concrete that hadn't, the team could successfully verify that direct air carbon capture had occurred. This method could be useful for the industrial sector and countries looking to offset their carbon emissions.

2023 is on the way to becoming the hottest year on record. Rice crops wilted in Japan and roads melted in the U.S. Despite international agreements and calls to action, greenhouse gas emissions from fossil fuels have continued to increase. If we are to prevent the planet from tipping over the critical threshold of a 2° Celsius temperature rise by 2100 (compared to preindustrial levels), we need to do more.

According to the United Nations' Intergovernmental Panel on Climate Change, reducing and preventing further emissions alone is not enough. We must also remove carbon dioxide from the atmosphere if we are to hit our target.

Direct air capture (DAC) pulls carbon dioxide from the air using chemicals or physical processes. Increasing the use of DAC technologies is part of the International Energy Agency's (IEA) net-zero emissions scenario, a proposed range of methods to enable the global energy sector to remove as much carbon dioxide (CO2) as it emits by 2050.

According to the IEA, industry was responsible for a quarter of global energy system CO2 emissions in 2022. Cement is the second most widely-used industrial product (after water), and it comes with a high environmental burden.

"As much as 800 kilograms of CO2 is emitted per ton of cement during its production, so reducing emissions has become a significant issue in the concrete industry," explained Professor Ippei Maruyama from the Department of Architecture at the University of Tokyo Graduate School of Engineering.

"Concrete has long been known to react with CO2 in the air to form calcium carbonate, an undesirable phenomenon because it induces corrosion of the steel bars inside concrete structures. However, the concrete industry is now considering ways to make effective use of this reaction."

Although problematic for construction, the reaction which causes calcium carbonate to form fixes or traps CO2, removing the gas from the atmosphere. Calcium carbonate is also found naturally in rocks, such as limestone, which are used in concrete manufacturing.

"This makes it difficult to distinguish whether or not CO2 identified in concrete has been freshly extracted from the air or comes from rocks," said Maruyama. "So we developed a method to verify this, which could be used to determine whether the concrete produced can be certified as offsetting CO2 emissions."

Researchers carried out the study by making hydrated cement paste samples as a concrete replica. After getting sufficiently hydrated, they ground the paste sample into powder, keeping the non-exposed powder contained and leaving the exposed powder open to the air.

After seven and 28 days, they dissolved the powder in acid to collect the gas and using a technique called accelerator mass spectrometry analyzed the ratio of several carbon isotopes (atoms with the same chemical properties but different physical properties), namely carbon-12, carbon-13 and carbon-14. This enabled the team to evaluate where the carbon came from, and whether it was already present in the raw materials, as the carbon ratios reflected the known proportion of carbon isotopes in the air at the time the gas was sealed.

Next, the researchers want to apply this lab-based method to real-world locations and test how the varied quantities of raw materials used in local concrete production may affect results.

"Fixing carbon dioxide from the air is certified as an act of offsetting CO2 emissions, so it is economically valuable in terms of emissions trading. Digging up calcium carbonate for use in concrete is not, so the distinction is very important and this research can help to support a healthy market," said Maruyama.

"We believe that carbon neutrality and a circular economy in the construction industry are essential to our future, particularly in Japan where this industry has a role in supporting business continuity and recovery from natural disasters."

More information: Zhenzhen Wang et al, Verification Method of Direct Air Capture by Cementitious Material Using Carbon Isotopes, Journal of Advanced Concrete Technology (2023). DOI: 10.3151/jact.21.934