This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Robot space maintenance based on human arm dynamics

On-orbit assembly has become a crucial aspect of space operations, where the manipulator frequently and directly interacts with objects in a complex assembly process. The traditional manipulator control has limitations in adapting to diverse assembly tasks and is vulnerable to vibration, leading to assembly failure.

To address this issue, Researchers at Beijing Institute of Technology propose a human-like variable admittance control method based on the variable damping characteristics of the human arm. This method can effectively increase the safety, robustness, and adaptability of robot space assembly. The team published their findings in Cyborg and Bionic Systems on September 6, 2023.

Robots are increasingly being used for maintenance and repair in space due to their greater adaptability to the harsh space environment compared to human astronauts. This trend is critical for the development of space technology, as it can help mitigate health risks for humans in space stations and address the challenges of repairing spacecraft in space.

Robotic assembly is a vital field of research that has seen important progress in recent years. Compliance control has emerged as the primary method for enabling robots to perform complex assembly tasks. However, compliance control places high demands on the manipulator's contact performance, making it challenging to achieve the required levels of precision and adaptability.

In response to these challenges, researchers have proposed various compliance control methods, including damping control, stiffness control, force/position hybrid control, and fuzzy adaptive control algorithms. These algorithms aim to improve the adaptability and efficiency of robots when performing assembly tasks, particularly in unknown environments.

Assembly tasks frequently involve contact between a manipulator and an object being assembled. To prevent excessive contact force from damaging the object, damping is necessary to dissipate energy and restrain vibration. Objects with larger damping consume energy more rapidly under external forces.

The human arm's musculoskeletal system can flexibly adjust damping to perform various tasks safely and stably.

To collect parameters such as contact force and velocity, the team established a dynamic data acquisition platform to capture human arm motion. The system's main components include a motion capture subsystem and a contact force measurement subsystem. An ATI omega160 6D force sensor is used to collect contact force data between the human hand and assembly parts, while end velocity data of the human arm are obtained using a Stereolabs ZED mini motion capture system.

"In order to gain a more accurate understanding of the motion characteristics of human arms, we use high-performance equipment to measure and analyze the obtained data," said Xiao Huang, a researcher at Beijing University of Technology.

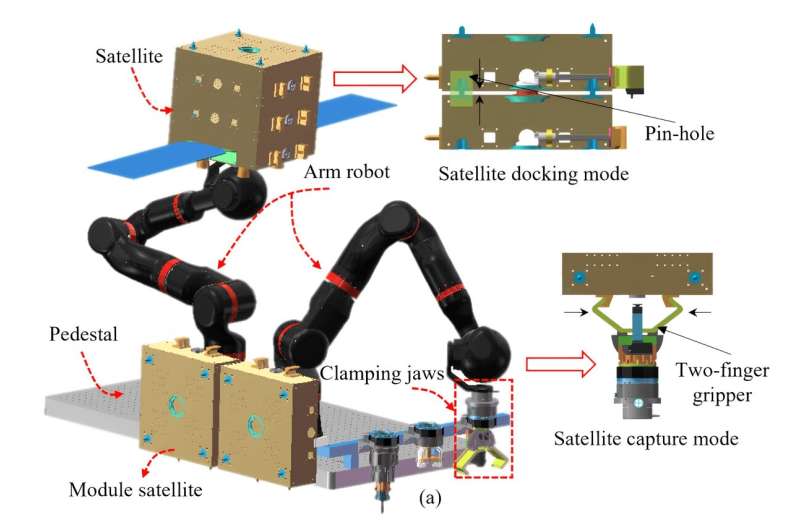

In order for the robot to better complete the assembly task, the researchers summarized the dynamic characteristics of the human by analyzing the movement data of the human arm during the assembly process and they applied this feature to robots. In addition, because satellite assembly tasks are diverse and contact patterns are complex, the research team analyzed various scenarios during the satellite assembly process and summarized three contact patterns for satellite assembly.

"This can help us better model contacts for robotic satellite assemblies and more accurately control the safe assembly of robots," said Xiaolei Cao, a researcher at Beijing University of Technology.

For the study, the team conducted space satellite assembly simulation verification through a ground experimental platform. Their robotic platform is capable of measuring forces and torques at the end of a robotic arm in the X, Y, and Z directions. They applied the human-like variable parameter admittance controller to the robot satellite assembly experiment and successfully verified the effectiveness of the human-like variable parameter admittance controller.

Human-like control strategies can improve the adaptability, precision, and controllability of robots performing space assembly and maintenance tasks. However, further research is necessary to enable robots to accomplish flexible assembly tasks comparable to real humans. Durable and reliable robots capable of withstanding harsh space environments are also needed.

"Advancements in humanoid control strategies can have important implications for the future of space exploration and development, further improving mission efficiency, safety, and reliability," said Zhihong Jiang, a professor at Beijing University of Technology.

The research team includes Xiaolei Cao , Xiao Huang, Yan Zhao , Hui Li and Zhihong Jiang from Beijing University of Technology, Zeyuan Sun from China Northern Vehicle Research Institute, Beijing; and Marco Ceccarelli from Department of Industrial Engineering, University of Rome Tor Vergata, Via del Politecnico.

More information: Xiaolei Cao et al, A Method of Human-Like Compliant Assembly Based on Variable Admittance Control for Space Maintenance, Cyborg and Bionic Systems (2023). DOI: 10.34133/cbsystems.0046